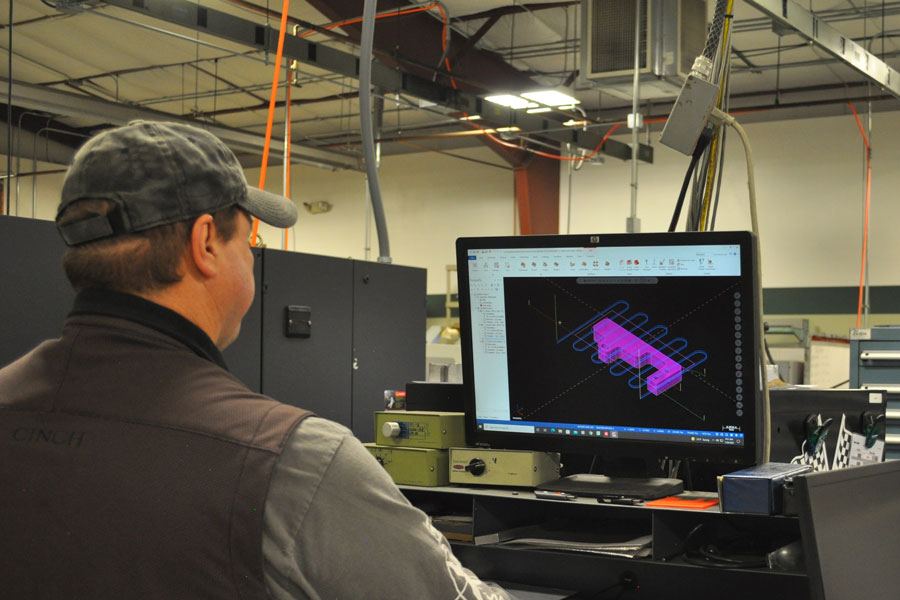

CNC Programming

As part of the continued growth and commitment to quality, IN-X Machine Inc. is now using MasterCam 2021 Software that greatly increases CNC programming efficiency, precision and overall quality. The software is able to import to machine all major brands of CAD systems including:

- Catia

- ACIS

- IGES

- DXF

- VDA-FS

- Parasolid

- SolidEdge Files

- SolidWorks Files

Highly Flexible, Fast, Precise Multi-Axis CNC Machining

Our manufacturing software reduces cost and increases productivity by including multi-axis CNC machining improvements increasing flexibility, increased production, and precision in turning related applications. Not to mention improvements in safety and speed allowing In-X Machine to streamline multi-axis CNC machining production.

In-X Machine’s multi-axis CNC machining service can work with CAD files from all major CAD software. Allowing for flexibility and precision regardless of where the file was created. Our software features single setup precision with lights-out production capabilities to increase speed to job completion.

Many detailed milling strategies are new in Mastercam 2021, allowing In-X Machine to be more efficient using fewer setups while creating an immaculate finish. We can also analyze the cut of the surface model and modify the direction as needed. This means we can apply multi-axis milling techniques to abstract unusual shapes. We also have a tool patch designed to produce the desired finish without multiple passes saving time and money.

Turning Related Application Precision

The Mastercam 2021 software has also improved support for modeling chuck jaws and chucks and you can now define them by selecting a solid model. Mastercam Mill-Turn supports collet chucks as individual component types. This gives us the ability to work with more machines.

Our solutions for Swiss machining jobs use Mastercam Lathe and mastercam mill with specialized post processors. Giving In-X Machine the ability to provide precise G-code to our Swiss turning machines.

Speed, Precision and Safety in CNC Programming

Advanced drill is a new tool path in our software that features a customizable multi-segment drill cycle that can be used for back spot facing as well as many drilling applications. The new Chamfer Drill toolpath chamfers holes after determining the correct depth based on the desired depth or width, lets you select different diameter holes or that are on different planes, and machine them with a single tool in one operation.

When creating a bounding box in Mastercam 2021, the new Wrap option allows you to create the smallest bounding box possible.

Different Styles of Multi-Axis CNC Machining

3-Axis Machining - The Most Common Technique

3 axis machining means that you are cutting parts on three axes; the X, Y, and Z axis. Originating in the 1800s, 3 axis machining has progress in technology and precision a lot since then. 3 axis machining is an accurate, multifunctional approach that is great for:

- Interactive Operation

- Drilling Precise Holes

- Milling Slots

- Automatic Operation

- Cutting sharp edges

3-axis milling can create similar products to 4 axis and 5 axis machines, although 3 axis machines lack in accuracy, detail and efficiency when compared with 4 and 5 axis machines.

4-Axis Machining - More Detail Than 3-Axis

4-axis milling makes improvements upon 3-axis machines in terms of capabilities and flexibility. While this is still a very popular option for many clients, more complex parts would be created faster and more precisely using the 5-axis machining technique.

5-Axis Machining - The Most Efficient, Precise Equipment Available.

The best CNC milling machines in our current market are 5 axis milling machines, this is due to their unmatched precision and speed to job completion. They continually outperform the 3 and 4 axis machines in efficiency, precision and tool flexibility. A 5 axis CNC machine center is capable of efficiently creating precise products and parts for the following industries:

- Medical

- Energy

- Medical

- Military

Our 5 axis CNC machine centers can handle the most complex designs and operate at an extremely tight tolerance. Our technology allows us to deliver exceptional accuracy while reducing setup time for complex, multi-sided part manufacturing.

IN-X Machine, Inc.

IN-X Machine, Inc.